Calibration and Advanced Torque system accessories

The Quad Plate enhances the efficiency of your System 4 or System 5 Digital Torque Tester when using an ML 250 Mechanical Loader. Up to four TT-Series Torque Transducers can be mounted to the plate, and rotated into position as needed!

These “L” brackets are ideal for mounting TT and STT-P Series torque transducers to a workbench or cart.

Torque wrench calibration can be done by hand - more or less. Since distance is a key component in the calculation of “force times distance”, the maintenance of the correct distance during calibration is extremely important in obtaining accuracy. Since the human hand is about 4” wide, the “load point” where force is applied to the tool is a variable - a variable that works against, instead of for, you.

Well designed mechanical loaders eliminate that variable, as well as errors caused by applying force at other than a 90 degree angle. They also reduce operator fatigue and improve productivity.

Take a look, and discover what a difference they can make!

Torque tool calibration requires attention to detail in every respect, and maintenance of records pertinent to all factors - as well as creating certificates of calibration for each calibrated item. When all of this can be automated the process becomes more efficient, less prone to error, and less costly to operate.

Torque Tool Manager, used with S/R digital torque testers, improves control and efficiency for almost all of the operations. Specifications and tester settings are stored in the software and downloaded to the tester exactly when needed. The technician is guided and supported by the software during the testing, and the results are captured, uploaded, stored and used to print the ceritificate when the testing is complete. Take a look at this efficient software!

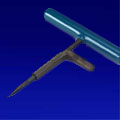

When you need torque higher than your maximum direct reading torque wrench capacity, a torque multiplier is often the solution you need.

The torque multipliers multiply your input torque by about 4 times (model dependent) and output the torque on the other end. Take a look!

Testing clutch, stall or pulse tools requires that the tools be able to rotate at operating RPM before the torque output is actually tested. S/R Rundown Fixtures enable you to achieve that requirement, while emulating either a hard or medium joint. See how much they can improve your power tool testing!

The Switch Box enables up to four transducers to be electronically connected to your System 4 or System 5 Digital Torque Tester. Switching among them is as simple as turning a knob. Take a look!

All of the torque transducers listed here are designed to work with both System 4 and System 5 Digital Torque Testers. Each has differing mounting options and/or mechanical loader compatibility. This chart will help you select the best transducer models for your application. See more information on our Torque Testers and Calibration Equipment Page.

Torque tester calibration is identical to torque tool calibration in its’ necessity, but of significantly greater technical difficulty in obtaining the required accuracy. Everything from the rigidity and stability of the mounting base to the distance from the center of the tester drive to the center of the cable of the weights used becomes critical for accuracy. Even the gravitational variation where the calibration testing is performed is important.

Go to our Torque Tester Calibration Equipment page to see the range of S/R offerings, and how we can help you obtain the accuracy critical to success.

Interchangeable Heads

Interchangeable Heads Crowfoot Adapter

Crowfoot Adapter CART Tool

CART Tool Color Coding Shrink Sleeves

Color Coding Shrink Sleeves Handle Extension

Handle Extension Grip Extension

Grip Extension Quad Plate

Quad Plate Transducer Mounting Brackets

Transducer Mounting Brackets Mechanical Loaders

Mechanical Loaders Torque Tool Manager Software

Torque Tool Manager Software Torque Multipliers

Torque Multipliers Rundown Fixtures

Rundown Fixtures Switch Box

Switch Box